IVIEWOPS

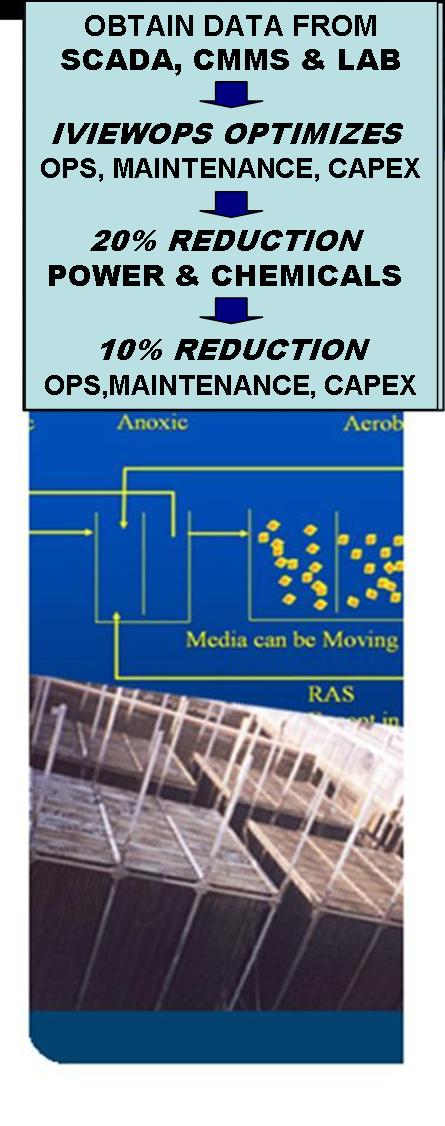

IViewOps2 is constructed on C# and Java, currently running on .NET. It has an asset based structure, with its models and algorithms geared for troubleshooting and plant optimization. It is being applied to full scale plants, storage, distribution, collection systems in Water and Wastewater Utilities and Chemical industries. The purpose is to identify and implement strategies optimize plants to reduce operating and life cycle costs while complying with permits for nutrient removal and reuse. From an asset management standpoint, it is used to find how to invest in the correct part of the plant infrastructure at the correct time with the correct size of project to upgrade capacity or performance.

IViewOps3 is the third generation of IViewOps for operations control and optimization, and for design analysis of Water and Wastewater plants.

AquaNET (Aquifas) has .NET interface developed before 2010 with Excel backend.

For Wastewater, the models include Headworks, Primary Treatment and Solids handling. Headworks include equalization, recycle from solids handling, primary clarification. Solids handling includes thickening, aerobic and anaerobic sludge holding tanks and digestion, struvite and vivianite formation, and dewatering. The speed and accuracy are designed for operations control and optimization, which exceed the requirements for design.

The algorithm that solves 120+ differential equations, including all features in ASM2D.The model includes simulation of Green House Gas (emissions). It breaks up ammonia oxidation for ammonia oxidizing bacteria (AOB) for ammonium-N to nitrite-N and nitrite oxidizing bacteria (NOB) for nitrite-N to nitrate; reduction to nitric oxide to nitrous oxide by some nitrifiers; four step denitrification by ordinary heterotrophs (OHO), polyphosphate accumulating bacteria (PAO), including GAO competition and high temperature reduction in Bio-P removal (IViewOps3) and methanotrophs (MHO). It has been applied to full scale plants to identify strategies to simultaneously enhance nutrient removal and reduce GHG emissions.

The models improve accuracy of biofilm simulations by using both a semi-empirical approach and a diffusional model that simulates substrates, electron acceptors and bacteria in multiple layers of the biofilm and a stagnant liquid layer, and connect the diffusional model to semi-empircal models.

It is similar to 1 & 2D models presented by IWA Task Group on Biofilm Modeling (Wanner et al., 2006).

OPERATIONS:

Aquifas+ can be applied as a plant CONTROLLER and OPTIMIZER that runs in conjunction processes, such as those for membranes or denit filters. It can be run at a process or whole plant level.

IViewOps can run with each specific equipment such as tanks and pumps, each specific hydraulic configuration based on tanks, pipes, pumps and valves in or out of service within each process in the plant. This helps understand how availability of assets affect operations. It can be run at the whole plant level to optimize operations across the primary, secondary, tertiary and solids handling systems; identify strategies to simultaneously improve operations and maintenance.

DESIGN:

The applications and models can be used by themselves or in conjunction with other simulators to improve the accuracy of their designs. If a plant is using IViewOps for operations, the engineer can use the setup at the plant which is calibrated to the plant and replicates the asset and hydraulic network to find better ways to upgrade the plant. The design will have a much greater accuracy and reliability.

|