|

|

|

The Aquifas and IViewOps products and applications are supported by individuals and teams who specialize in plant and process design, operations, optimization and asset management. The products and applications are supported through agreements and partnerships in different geographies. Aquaregen, Virginia Tech Occoquan Program and Maryland Center for Environmental Training - MCET lead elements of the development, optimization and asset management, and testing. They support training and technical assistance.

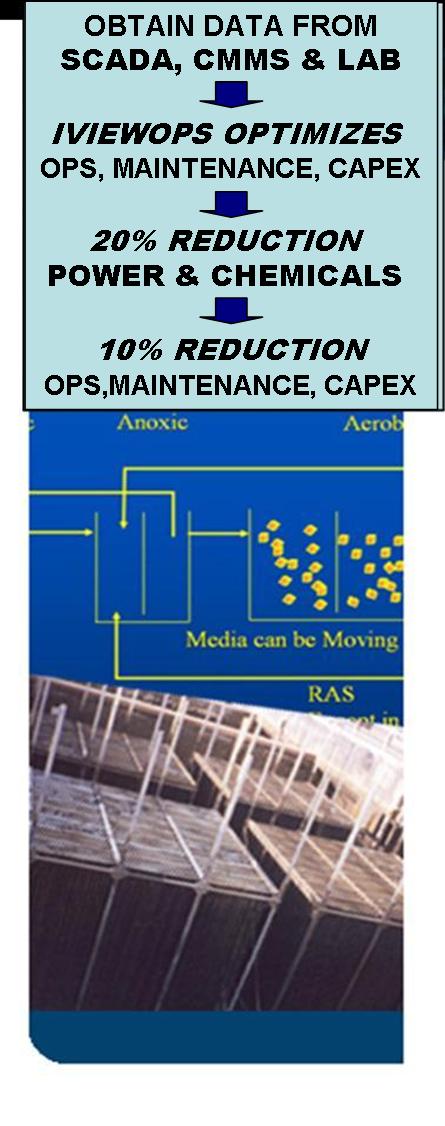

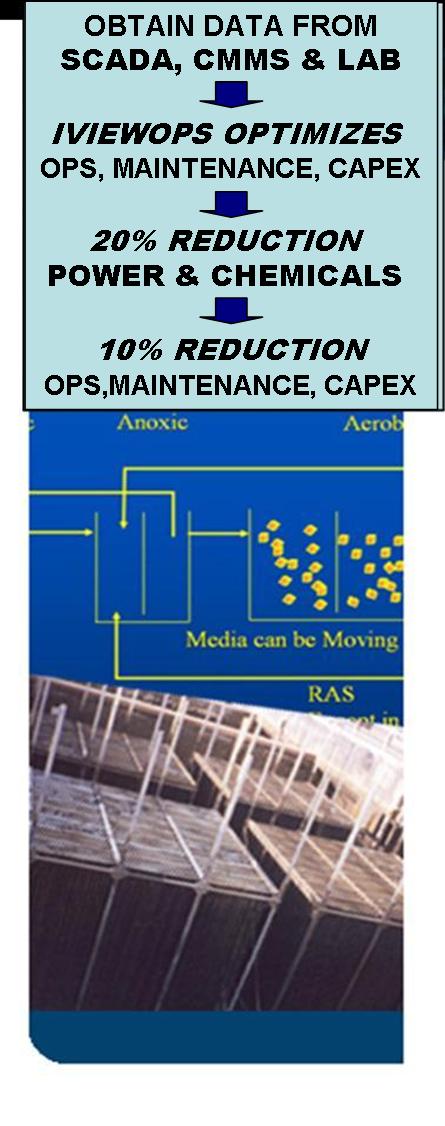

The products focus on simultaneous management of effluent, equipment and assets, energy and emissions. The emphasis is on operations optimization and asset management in ENR, membrane and biofilm technologies to improve reliability and reduce operating and life cycle costs. IViewOps has also proved to be an excellent tool to improve plant upgrade designs based on knowledge from optimization of existing operations. |

|

|

|

|

Users can contact members supporting the products with questions about plant design and optimization, process modeling, media and membrane applications. |

|

For product and related service questions

Email: cs.iviewops@gmail.com

For plant design and operations training questions, users can send an email to be contacted by independent representatives or entities in their geography.:

Instructional support is provided by individuals, Training Centers and companies.

To be assigned to the best support, one can contact the IViewOps team at Virginia Tech, Aquaregen or MCET or email cs.iviewops@gmail.com

|

|

|

|

|

| This Unified Model for drinking water and wastewater, which includes physico-chemical and biochemical systems, biofilm, activated sludge and membrane systems is the synthesis of the process and asset management models used in AquaNET, Aquifas and IViewOps. It has been developed and published over a period of 20 years. The effort included contributions by academics and technologists, various media and membrane manufacturers. The bench scale pilot studies with media to develop the semi-empirical and biofilm diffusional models were conducted by Drs Dipankar Sen and Clifford Randall at Virginia Tech, Blacksburg, VA. Full-scale installation and testing of processes and models were conducted in collaboration with managers, operators and engineers at various utilities in the drinking water and wastewater sectors. Subsequently, the equations for the semi-empirical model and the parameters were published by these authors at WEFTEC 1996, in http://www.e-wef.org Investigation of Hybrid Systems for Enhanced Nutrient Control ISBN 1893664066 and ASCE http://cedb.asce.org Jour Env Engr Vol 131 (11) Nov 2005 ; additional improvements were presented in papers at WEFTEC 2005, 06, Nutrient 2007 (Session 12), WEFTEC 2007 and WEF http://www.waterpractice.org Water Practice Vol 1 (5) 2007 ; http://www.wer.org Water Environment Research Vol 80 (5) 2008. Today, the models have been verified at some of the leading water, wastewater and water reuse plants. Historically, both the semi-empirical and biofilm diffusional models were verified in full scale using data from the IFAS plant at Broomfield (2006-08). The activated sludge and membrane components were developed in parallel in collaboration with manufacturers and plants (Redlands, CA). The application of the model to membrane systems is presented at WEF Membrane 2008 and WEFTEC 2009. Ongoing research includes development of 30x faster algorithms by Adnan Lodhi; expansion of the models into plant wide asset, energy and emissions management. |

|

|

|

|

| Through the .NET platform and use of C# and Java, the applications can be enhanced and customized to fit the needs of individual plants and Utilities. External links can be developed to SCADA and power systems. |

|

|

|

|

| The applications have been developed over by specialists in math algorithms, process design, operations and asset management. In general, it uses an open source framework geared to satisfy the needs engineers and operators who wish to develop designs that are cost effective, require less land area and maximize use of existing facilities. When calibrated, the Aquifas model generates results that are comparable to the most advanced dynamic simulation models. For IFAS, MBBR and Membrane Bioreactors, Aquifas can simulate complex parameters such as biofilm thickness, VSS and membrane operation better than other models. |

|

|

|

| |

| |

|

|